Italian National Space Day Workshop

The Italian National Space Day Workshop was successfully held on December 16, 2024, by the Aerospace Engineering Department of Izmir ...

Project Management in Aerospace Seminar

Our university's Aerospace Engineering department organized a seminer called ''Project Management in Aerospace''. On Wednesday, October 30, Timur Akgül visited our ...

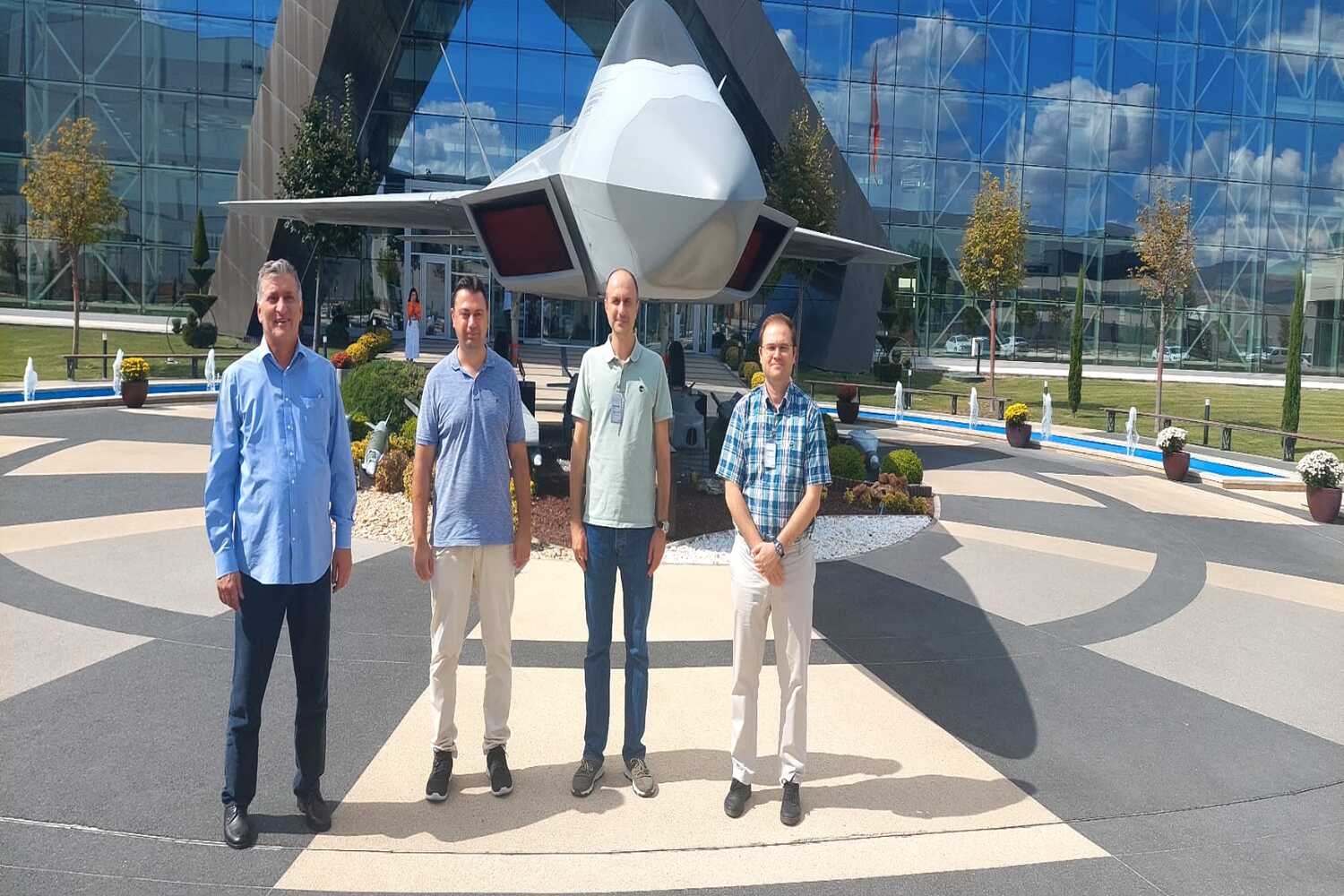

Visit of TAI

On September 20, 2024, a Technical Trip was held to TAI Aerospace Industry (TAI) by faculty members of the Aerospace ...

‘Çalıkuşu’ is the winner

Students of Izmir University of Economics (IUE) won first place in the Helicopter Design Competition organized within the scope of ...

Space Education in England

Burak Köse, a graduate of the Department of Aerospace Engineering at Izmir University of Economics (IUE), has been accepted for ...

Teknofest 2024 Helicopter Design Competition

Our ECO-Dynamics team, consisting of students from the Aerospace Engineering department, was deemed worthy of the 'best presentation award' in ...

Visiting of the Murat Özpala

TAI Training Aircraft Lead Flight Test Pilot Chief Murat Özpala, who successfully carried out more than 2000 hours of experimental test ...